tl;dr: I

took a welding class, now I’m inspired about the possibilities of future (and futuristic) manufacturing and fabrication.

Intro to Metal Working Workshop

|

| My classmates learning the tricks of the trade. |

I recently finished taking an Intro to Metal Working workshop at the Makerhaus. It was a brief intro into using various tools and techniques to cut, form, and attach metals including a MIG welding and an oxyacetylene torch. Other tools I used include: a lathe, sheet metal bender, band saw, metal sander, metal shears, drill press, and metal grinders, etc.

It was pretty fun. Mostly we just used tools to break apart

and destroy things and then weld them back together into something.

I made a shelf out of old bike parts: gears and bike chain.

I’m pretty proud of it. The welds are all kinda, ehh-quality, but that is more to do with rushing through them than

my lack of skillz. I’m actually impressed with my welding ability (I thought I

was going to be terrible), but I’m alright at it.

| |

The shelf I made.

|

|

| Displaying Thrift Store trinkets. |

| Anyway. I also welded these gears together at the end just for fun! I call it art! |

|

| Welding Practice = Art. |

It was fun and interesting and I really want to own and use

a MIG welder. For what, I haven’t yet figured out, but I’m sure there is a

reason, (and maybe a practical one) that I can use to justiy buying a MIG

welder? Maybe just to be artistic and

bring out the artistic artist in myself and make art.

The workshop was an overall good experience, but if I was to

go back in time, personally I would probably skip this class and put the money towards a MIG welder, because let’s face it, while in-person instruction is very

helpful, we do have the internet!

With a little common sense, care, and patience you can teach yourself

practically anything. So I would probably take that route: get free knowledge and instruction and

invest my money in the tools. A class

like this does help build confidence and gives you the kick-in-the-pants to

jumpstart you into such an unfamiliar trade/hobby (such as welding) that many

of us need to get into something like this.

|

| A scrap-metal holiday message from the Makerhaus Metal Shop. |

The Makerhaus

The other benefit of the class was to get acquainted with the

Makerhaus itself. Makerhaus is kind of

an incubator and facilitator for creative people. They “provide the resources,

education and community for creative minds to make, invent, prototype and

explore without boundaries.” It’s ideal for entrepreneurs, Kickstarters, and small

businesses, or anyone with a project to do, who doesn’t want to invest in an

entire shop.Its another example of a type of Collaborative Consumption: access over ownership.

|

| The Makerhaus (click for an article about it in Seattle Met) |

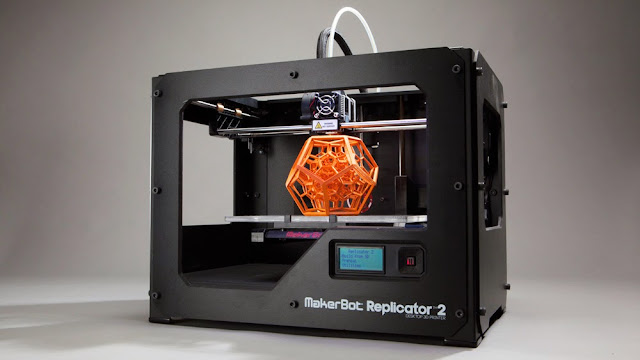

Membership provides access to all kinds of useful tools with

a full woodshop, full metal shop and a plethora of crazy futuristic tools

that connect Computer

Aided Drafting and Design (CADD) to the real world with such fancy tools as

a laser

cutter, CNC

Router, and multiple 3D printers.

So while I am not a member, (its expensive!) it was cool to

be introduced to what access to this place is all about. It was cool just to

see a 3D printer working. It was also very inspiring at what is possible in the

realm of taking an idea in your brain and transferring it into reality,

especially with access to these kinds of futuristic tools. So now I segue from

old school manufacturing (woodshops and welders) into…

The Future of Things and Your Creativity

The future is filled with endless possibilities for the creative

person. Tools that were purely science fiction, or even beyond comprehension just a few years ago, are

rapidly becoming accessible and affordable to masses. It’s truly a revolution that

has gone mostly unnoticed. Just about anyone

can design, prototype, and build just about anything

you can dream up; if it obeys the laws of physics (and fits the limitations of

the tools, but those limitations are dwindling.)

You can literally print out structures which are more intricate

and complex than can be created by any other manufacturing process. Essentially

allowing you to leap-frog 20th

century manufacturing techniques and create and manufacture complex items on

your desk top, from your desktop.

This revolution in manufacturing is built upon the technology of 3D Printers, 3D Scanners, and of course the open-source internet. The internet is now a growing source of 3D things. For example: Thingverse is online, open-source, crowd-sourced, repository for FREE 3D printable things.

This revolution in manufacturing is built upon the technology of 3D Printers, 3D Scanners, and of course the open-source internet. The internet is now a growing source of 3D things. For example: Thingverse is online, open-source, crowd-sourced, repository for FREE 3D printable things.

|

| An example of a 3D Printer |

The possibilities:

Practical: Can’t find that discontinued window knob for your 1983 Toyota pickup? Print one!

Creative: Have an idea for a custom iPhone case? Draw it in CAD and Print it!

Piracy: Want to reproduce that unique item you found at the Thrift Store! Scan it and Print it!

The possibilities are absurd.

If that isn’t enough inspiration to go out and create, maybe this will help.

The good thing is this technology is exponentially improving and becoming cheaper. This funded Kickstarter campaign (goal: $50,000. $651,000 raised!), aims to create world’s first $100 3D printer AND scanner.

More information on the future of 3D things.

TED Talk Video: A primer on 3D printing

Video on the MakerBot 3D Printer

MakerBot.com

Thingverse.com